Fixed Spot Non-Contact Thermometers / Pyrometers

Our advanced non-contact infrared pyrometers provide high precision temperature information for a wide range of industrial processes, covering a broad temperature range with an extensive number of spectral bands. Backed by our decades of experience and application support, they deliver the data required to keep industrial processes running safely and efficiently.

PYROMETER SELECTION

The best pyrometer for a particular application depends on the product to be measured and its surface condition as well as the process environment and control system.

Mono pyrometers measure at a single wavelength of infrared. For accurate measurement, they need a clear view of the product and surface emissivity must be known.

Ratio or Two-Colour pyrometers measure at two separate wavelengths to correct for dust, dirty windows and obscuration - or for changing emissivity as long as both wavelengths are affected proportionally.

Application pyrometers are required for processes such as aluminium processing and galvanizing / galvannealing which change the chemical nature of the surface. SPOT+ Pyrometer Type Selction AMETEK Land offer three families of fixed spot pyrometers. Within each product family, there are standard and fibre-optic variants with various wavelength options to cover different temperature ranges.

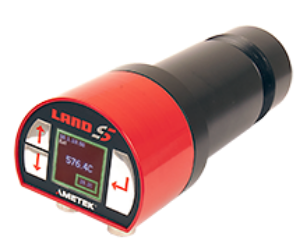

SPOT+ smart high precision pyrometers with onboard processing, visible light process video, onboard display and control panel, local I/O plus remote control over ethernet

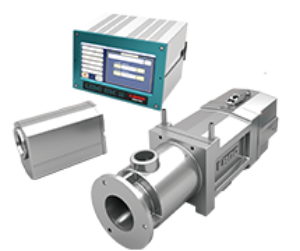

System 4 high precision Industrial process pyrometers with simple analogue I/O, with additional processing and display available via an external processor.

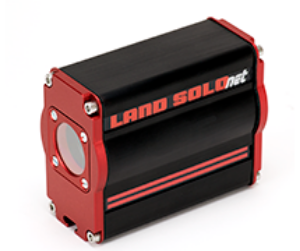

Compact OEM pyrometers such as the SOLOnet compact series, IQ rugged series and SPRINT8 loop-powered pyrometers are miniaturised devices designed for OEM and customer integration.